Sustainability is a complex term which is interpreted differently by different sectors. The fact that it is open to interpretation makes it challenging to define Sustainability for all. Due to this, practicing sustainable practices at personal, corporate and government level remain uncertain (Lewis, Fitzpatrick, Verghese, Sonneveld, & Jordon, 2007).

A key part of sustainability includes managing the waste and reducing the use of non-biodegradable materials. This has emphasized and promoted innovative advancements in production in industrial sectors. Sustainable production, with reduced waste in the overall lifecycle of a product, has been the primary goal.

Sustainable packaging is an important part of this process and has a large role to play in the overall achievement of making the sustainable guidelines. That’s why sustainable packaging materials and process are making a buzz around the globe, especially due to the pandemic and the associated safety requirements. Many manufacturing businesses are incorporating sustainability practices with increase in online food orders, delivery and comfort of packaged food items. The areas of focus for sustainable packaging revolve around the design models and their effectiveness in balancing the economic profits and environmental benefits (Nordin & Selke, 2010). Although sustainable packaging is receiving the attention to comply with the sustainable developmental goals, it is still an evolving field.

The definition of sustainable packaging…

There isn’t any universal definition providing the constituents of what entails a sustainable package (Sonneveld, James, Fitzpatrick, & Lewis, 2014). So, we identified three important indicators to define sustainable packaging:

- The lifecycle of packaging materials is crucial to understand the scope of altering the materials;

- Interaction between the product and the package. This is the most important aspect to be considered especially for food items (eg. Pizza);

- It needs to consider the impacts that are caused on the environment, people and businesses.

As per the Sustainable Packaging Alliance, the definition of sustainable packaging must also include social, economic and environmental goals. For these goals, certain key principles are provided to evaluate the performance of the packaging based on its materials, life cycle and impacts. The four principles are:

- Effectiveness: The packaging itself has a value which it can add to the supply chain. These can be identified with the help of indicators such as reduced waste, improvement in functionality, reducing overly packaging materials at reduced costs.

- Efficient: the design of the packaging must be energy efficient throughout its life cycle.

- Cyclic: The circular economy in packaging must be enhanced. The materials used in packaging should be used in a cyclic manner naturally or through industrial systems.

- Clean: The packaging itself should be clean or non-toxic. The components used in the packaging materials such as inks, dyes, adhesives should not harm the ecosystems and human health.

These four principles are crucial especially for the food industry. In addition, the packaging must satisfy functional needs like product-packaging ratio, user-friendly design, and must attract consumers.

Sustainable packaging in the fast-food business: A case study

The fast-food industries in India are a major player in this sector. McDonalds, KFC, Pizza Hut, and Dominos chains are widely operated in the country and have become a part of daily lives of Indians. Home deliveries have made the brands more accessible at affordable prices. With the rise in the demand of home delivered food, the packaging has had a significant cost associated with it.

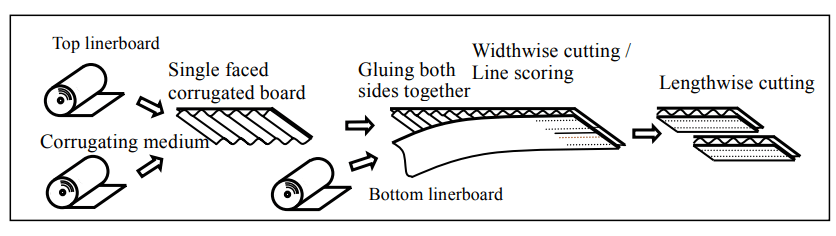

Fast-food are usually served and delivered in corrugated boxes. Corrugated boxes are preferred to balance the need to protect the product and material efficiency (Dominic, Östlund, Buffington, & Masoud, 2014). A corrugated cardboard is a stiff, strong, and light-weight material made up of three layers of brown Kraft paper. These boxes are user-friendly and can be made more attractive with colorful prints.

The colorful corrugated cardboard is made into boxes using various forms of adhesives. The adhesives are used to join the medium to the single facer and double facer line. Four main components make a typical corrugating adhesive: water, starch, caustic, borax (Yang; Liu; Han, 2008).

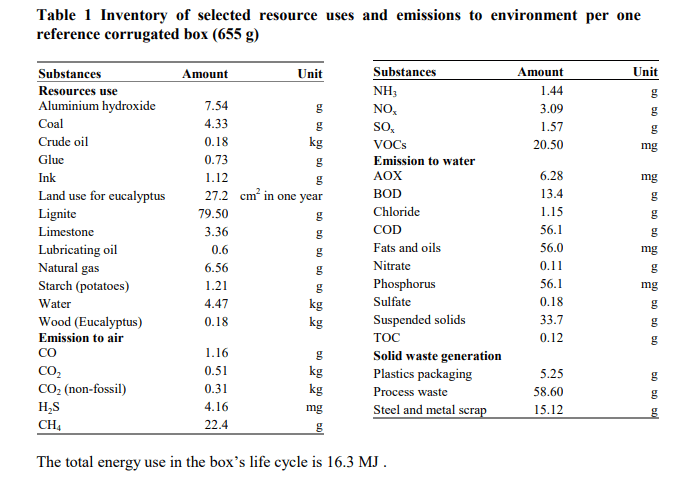

These chemicals are not only harmful for the human health but also have a severe impact on the environment (Steeman, A, 2015). In a life cycle impact assessment of corrugated box, five major environmental impacts were observed: global warming, acidification, eutrophication, ozone formation and solid waste generation.

The five impacts of corrugated boxes…

During production, the boxes require energy from steam and electricity which contributes to the global warming. The acidification and smog formation is at the end life of these boxes. When discarded in the landfills the NH3 released contribute to the acidification. Similarly, eutrophication is also identified at this stage as substances in the cardboard release ammonia and phosphate which contaminate the surrounding land and water bodies. Eutrophication also happens at the beginning of cleaning process of the pulp out of which these boxes are made. The waste generated during the making of these boxes and its total life cycle contributes about 65% to the total waste generation (Ongmongkolkul, Nielsen, & Nazhad, 2001). The anaerobic decomposition of corrugated boxes is the one step that contributes maximum to the environmental degradation. Proper management of life cycle of packaging is becoming of paramount importance (Lee & Xu, 2005).

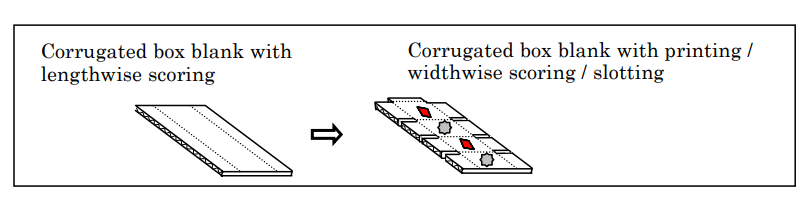

Other materials such as adhesives, inks and dyes used for beautification have an additional impact on the environment. Joint adhesives are used to bind the cardboard layers in making one whole sheet as shown in the image below.

The adhesives used are generally made from glue starch. Caustic soda and boric acid is mixed to get the right consistency and adhesiveness of the glue. Printing inks have too evolved from oil-based inks to flexo inks. This type of inks has quick drying quality and is made up of synthetic resins which are hazardous if mixed with water (Yang; Liu; Han, 2008).

Steps towards sustainability…

Several alternatives have been introduced in the market to replace the traditional corrugated boxes. To reduce the environmental impacts of corrugated boxes, using bio-based materials and redesigning the boxes is a way forward.

Several studies have also been conducted to replace the composition of packaging with bio-based materials (Khalil, et al., 2016). Bio-based plastics have also been used as a sustainable alternative for food packaging in different countries. According to the European standard EN 16575, bio-based is defined as ‘derived from biomass’. These natural polymers have certain environmental advantages: they can biodegrade quickly and with minimal pollution (if done right). In terms of attractiveness and user-friendliness, advancements in bio-plastics and starch-based material have opened a wide spectrum of possibilities. (Gadhave, Das, Mahanwar, & Gadekar, 2018).

For example, Polylactic acid (PLA) is a bio-based plastic that has numerous benefits for packaging. It provides transparency like other plastics, gloss, stiffness, blocks the aromas and is printable. Switching to bio-materials for food industry will reduce the impacts on environment and waste generated to great extents. (However, the material is often only biodegradable in industrial composting facility and a lot depends on the waste collection and processing protocols of the city).

Starch-based plastics are another example that have been developed with several properties that make it suitable for carrying food products. Application of antimicrobial film helps in extending the shelf life of the food product and prevents microbial growth on food products. Moreover, starch based polymers provide an additional heat sealing property. Hence food delivery with this packaging could help in keeping the product’s temperature intact (Gadhave, Das, Mahanwar, & Gadekar, 2018).

Conclusion

Fast-food packaging has been causing various environmental issues due to its one-time use. The implementation of sustainable packaging would minimize the impacts and provide scope for conserving the natural resources used in making one corrugated box. Bio-materials seem to be a promising alternative. The higher cost of bio-materials currently remains an issue. However, with the rising consumer awareness and the mounting waste management problem in India, switching materials is extremely important. Companies will also take this seriously if they are tagged with Extended Producer Responsibility (EPR).

References

Bucci, D. Z., & Forcellini, F. A. (2007). Sustainable Packaging Design Model. London: Springer, London.

Chitnis. (2019). A Study on Scenario of Fast-Food Industry in India. ResearchGate.

C.Mendes, A., & Pedersen, G. A. (2021). Perspectives on sustainable food packaging:– is bio-based plastics a solution? Trends in Food Science & Technology, 839-846.

Chiellini, E. (2008). Environmentally Compatible Food Packaging. England: Woodhead Publishing Limited.

D.Steenis, N., Lans, I. A., Herpen, E., & Trijp, H. C. (2018). Effects of sustainable design strategies on consumer preferences for redesigned packaging. Journal of Cleaner Production, 854-865.

Dominic, C., Östlund, S., Buffington, J., & Masoud, M. M. (2014). Towards a Conceptual Sustainable Packaging Development Model: A Corrugated Box Case Study. Packaging Technology and Science, 397-413.

Gadhave, R. V., Das, A., Mahanwar, P. A., & Gadekar, P. T. (2018). Starch Based Bio-Plastics: The Future of. Open Journal of Polymer Chemistry, 21-33.

Heredia-Guerrero, J. A., Benítez, J. J., Cataldi, P., Paul, U. C., Contardi, M., Cingolani, R., et al. (2017, January 5). All-Natural Sustainable Packaging Materials Inspired by Plant Cuticles. Advanced Sustainable Systems.

Khalil, H., Y.Davoudpour, K.Saurabh, C., S.Hossain, M., Adnan, A. S., R.Dungani, et al. (2016, October). A review on nanocellulosic fibres as new material for sustainable packaging: Process and applications. Renewable and Sustainable Energy Reviews, pp. 823-836.

Lee, S., & Xu, X. (2005). Design for the environment: life cycle assessment and sustainable packaging issues. International Journal of Environmental Technology and Management.

Lewis, H., Fitzpatrick, L., Verghese, K., Sonneveld, K., & Jordon, R. (2007). Sustainable Packaging Redefined.

Ma, X., & Moultrie, J. (2017). What Stops Designers from Designing Sustainable Packaging?—A Review of Eco-design Tools with Regard to Packaging Design. International Conference on Sustainable Design and Manufacturing (pp. 127-139). Springer, Cham.

Martinho, G., Pires, A., Portela, G., & Fonseca, M. (2015). Factors affecting consumers’ choices concerning sustainable packaging during product purchase and recycling. Resources, Conservation and Recycling, 56-68.

Meys, R., Frick, F., Westhues, S., Sternberg, A., Klankermayer, J., & Bardow, A. (2020). Towards a circular economy for plastic packaging wastes – the environmental potential of chemical recycling. Resources, Conservation and Recycling.

Nordin, N., & Selke, S. (2010). Social aspect of sustainable packaging. Wiley Online Library, 317-326.

Ongmongkolkul, Nielsen, & Nazhad, 2001. (n.d.). Life Cycle Assessment of Paperboard Packaging Produced in Thailand.

Siracusa, V., & D.Rosa, M. (2018). Sustainable Packaging. Sustainable Food Systems from Agriculture to Industry, 275-307.

Steeman, A. (2015, August 17). WordPress. Retrieved from Best In Packaging: https://bestinpackaging.wordpress.com/2015/08/17/health-risks-in-pizza-boxes/

Sonneveld, K., James, K., Fitzpatrick, L., & Lewis, H. (2014). Sustainable Packaging: How do we Define and Measure It? Researchgate.

Yang; Liu; Han, 2008. (n.d.). Life Cycle Assessment System Design for Packaging Industry. Proceedings of the 17th IAPRI World Conference on Packaging China.

I think they’re making great headway in sustainable fast food. Unfortunately the smaller chains are the ones that often use items that can’t be recycled.

I think the problem is lack of funding in sustainability in smaller businesses.

LikeLike

Indeed very informative from ABC of pamaterials to the end suggesting solutions.

In current scenario of Global warming – pollution – need of conservation of natural resources – very educative

Kudos Riya – keep it up.

LikeLiked by 1 person

Sustainable packaging is ideal for fast-food delivery and helps the environmental performance. Thank you 😊

LikeLiked by 1 person